The Art of Custom Motors Transforming Industries from HVAC to Oil and Gas

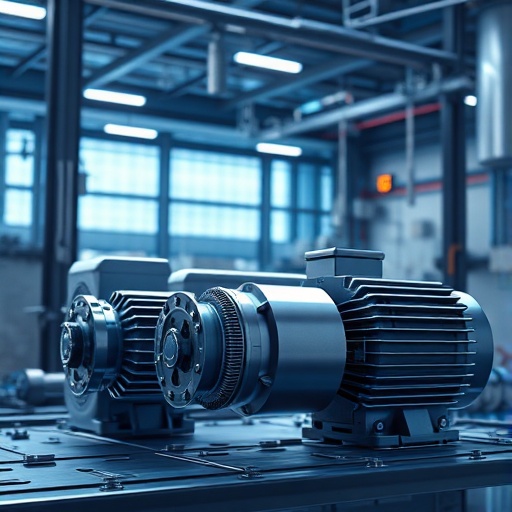

Understanding Custom Motors and Their Applications

Types of Custom Motors: AC and DC Variants

Custom motors drive innovation across industries by tailoring electric power to precise needs. Engineers design these motors to match specific performance demands, whether in heavy machinery or delicate equipment. AC motors, including single phase and three-phase variants, excel in applications requiring constant speed and high torque. They adhere to standards like NEMA and IEC for reliability in North America and beyond. DC motors, on the other hand, offer superior control over speed and direction, making them ideal for variable-load scenarios. Custom motor builds often blend these types, incorporating features like low inductance for efficient energy transfer. For instance, a custom AC motor might power conveyor systems in factories, while a DC variant drives precision tools. Related searches for custom motor vehicles highlight how these principles extend to electric vehicles, where torque motors ensure smooth acceleration. In motors customization, experts focus on weight reduction and lead-free materials to meet environmental regulations. This versatility transforms standard components into bespoke solutions, boosting efficiency and longevity. Companies seeking custom performance motors turn to specialized distributors for AC and DC options that integrate seamlessly into existing setups.

The Role of Custom Motors in HVAC Systems

HVAC systems rely on custom motors to maintain optimal indoor environments in commercial buildings and industrial facilities. These motors power fans, pumps, and compressors, ensuring efficient air circulation and temperature regulation. A customized motor in an HVAC unit adjusts speed dynamically to match demand, reducing energy consumption by up to 30 percent. Mechanical engineers specify single phase AC motors for residential applications, while three-phase versions handle larger commercial loads. Key features include robust bearings to withstand continuous operation and voltage tolerances for fluctuating power supplies. In America, where energy efficiency standards drive innovation, custom motors incorporate advanced controls to minimize noise and vibration. For wastewater treatment plants integrated with HVAC, these motors prevent overheating during high-humidity cycles. Searches for custom power motors reveal their growing use in smart HVAC setups that connect to IoT for real-time monitoring. Distributors provide information on custom motor parts like windings optimized for low inductance, ensuring reliable performance. This engineering precision not only cuts operational costs but also extends equipment life, making custom motors indispensable in modern climate control.

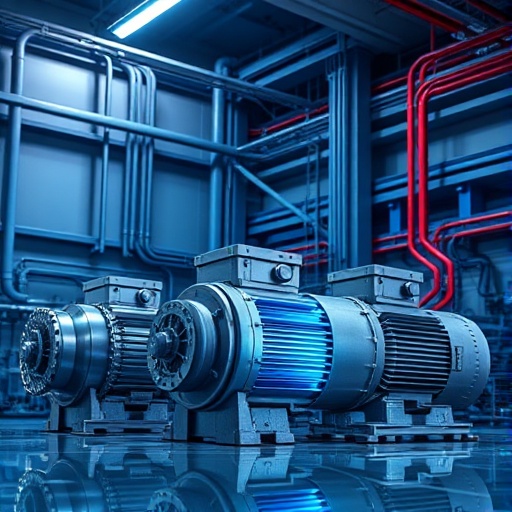

Innovative Uses of Custom Motors in Oil and Gas

The oil and gas sector harnesses custom motors to tackle harsh environments and complex operations. These motors drive drilling rigs, pumps, and valves, enduring extreme temperatures and corrosive conditions. A torque motor, for example, delivers high starting torque for submersible pumps in offshore platforms. Engineers customize DC motors for variable speed control in exploration equipment, enhancing precision during seismic surveys. In refineries, AC motors with IEC-compliant enclosures protect against dust and moisture. Custom motor vehicles, like specialized transport rigs, incorporate permanent magnet motors for fuel efficiency. The industry's demand for motors custom build pushes manufacturers to integrate features like high voltage ratings and low weight designs for easier installation. Bearings engineered for shock resistance prevent failures in vibrating pipelines. Related queries on customized motors underscore their role in automating extraction processes, where brushless DC motors reduce maintenance needs. In North America, regulatory pressures favor lead-free custom motors that align with safety standards. This innovation not only boosts productivity but also minimizes downtime, revolutionizing how oil and gas companies operate in remote and challenging terrains.

Engineering Custom Motors: Design and Manufacturing

Key Engineering Considerations for Custom Motors

Engineers approach custom motor design with a focus on application-specific challenges, ensuring seamless integration and peak performance. They evaluate factors like load requirements, environmental exposure, and power source compatibility from the outset. For electric custom motors, selecting between AC and DC variants hinges on speed control needs—AC for steady operations, DC for precise adjustments. Mechanical engineers prioritize weight and size to fit constrained spaces, such as in HVAC enclosures or oil and gas tools. Inductance levels influence efficiency, demanding careful coil winding to avoid energy losses. Manufacturing processes incorporate NEMA standards for mounting and IEC for international compatibility. Custom motor parts, like specialized shafts, undergo rigorous testing for durability. In America, where innovation thrives, engineers collaborate with distributors to source materials that meet torque motor specifications. Searches for motor custom reveal the emphasis on scalability, allowing prototypes to evolve into production runs. This meticulous engineering not only addresses current demands but anticipates future upgrades, delivering motors that outperform off-the-shelf alternatives in reliability and efficiency.

The Importance of Bearings and Torque in Motor Performance

Bearings and torque define the backbone of custom motor reliability, directly impacting speed, lifespan, and operational smoothness. High-quality bearings reduce friction, allowing motors to handle heavy loads without excessive wear. In torque motors, engineers select sealed bearings to shield against contaminants in wastewater or oil and gas settings. Torque output, measured in Newton-meters, ensures motors start and maintain motion under demanding conditions, like pumping viscous fluids. Custom designs optimize torque curves for applications requiring instant response, such as HVAC dampers. Mechanical engineers calculate bearing preload to balance axial and radial forces, preventing misalignment. Low-weight bearings contribute to overall motor efficiency, crucial for portable custom motor vehicles. Related searches for custom performance motors highlight how enhanced torque reduces energy draw, lowering costs in single phase AC setups. During manufacturing, torque testing verifies performance against voltage fluctuations. Distributors provide information on bearing materials resistant to high temperatures, extending service intervals. This focus on bearings and torque elevates custom motors from basic components to engineered powerhouses that drive industrial success.

Integrating Temperature Control and Voltage Specifications

Temperature control and voltage specifications form critical pillars in custom motor engineering, safeguarding performance in diverse conditions. Engineers embed sensors to monitor heat buildup, preventing insulation degradation in high-temperature oil and gas environments. Voltage ratings, often customized from 12V DC to 480V AC, match power supplies while incorporating safeguards against spikes. In HVAC systems, motors with integrated cooling fins maintain efficiency during prolonged runs. Permanent magnet motors benefit from low-temperature coefficients, ensuring stable torque across ranges from -40°C to 150°C. Custom motor builds address inductance effects that amplify heat, using advanced materials for better dissipation. Mechanical engineers specify enclosures with ventilation for wastewater applications prone to humidity. Searches for customized motors emphasize voltage flexibility for global deployments, adhering to NEMA and IEC norms. In America, energy codes push for designs that optimize single phase operations without overheating. Distributors stock parts like thermal protectors, streamlining integration. This holistic approach to temperature and voltage not only enhances safety but also maximizes motor longevity, making custom solutions indispensable for reliable industrial automation.

The Impact of Custom Motors on Various Industries

Custom Motors in Wastewater Management

Wastewater management depends on custom motors to power pumps, aerators, and mixers that treat vast volumes of effluent daily. These motors withstand corrosive chemicals and submersion, with IP-rated enclosures protecting internals. DC motors provide variable speeds for fine-tuning aeration levels, optimizing oxygen transfer without excess energy use. Engineers design torque motors to handle sludge viscosity, ensuring consistent flow in treatment plants. Bearings resistant to abrasive particles extend operational life in gritty environments. In America, where strict EPA regulations govern, custom motors incorporate low-lead components for environmental compliance. Voltage specifications accommodate grid variations common in remote facilities. Related searches for motors customization reveal innovations like brushless DC motors that cut maintenance by eliminating brushes prone to corrosion. Mechanical engineers collaborate on single phase AC options for smaller plants, balancing cost and performance. Custom motor parts, such as reinforced shafts, prevent breakdowns during peak loads. This tailored engineering slashes downtime and energy bills, transforming wastewater operations into efficient, sustainable processes that protect public health and ecosystems.

Enhancing Efficiency in HVAC Through Custom Engineering

Custom engineering elevates HVAC efficiency by delivering motors precisely tuned to system dynamics, from residential units to massive commercial complexes. Engineers optimize AC motors for variable frequency drives, allowing speed modulation that matches cooling demands and saves up to 40 percent on power. Torque specifications ensure quick fan startups, improving air distribution. Temperature controls integrate with thermostats for proactive heat management, preventing overloads. In high-rise buildings, low-weight custom motors reduce structural strain while maintaining robust performance. NEMA-compliant designs facilitate easy retrofits in existing HVAC setups. Searches for custom power motors underscore their role in smart buildings, where IoT connectivity enables predictive maintenance. Mechanical engineers focus on bearings that minimize vibration, enhancing occupant comfort. Voltage tolerances handle brownouts common in urban grids. Distributors offer information on inductance-lowered windings for smoother operation. In oil and gas facilities with integrated HVAC, these motors endure dusty conditions without faltering. This precision engineering not only boosts energy savings but also aligns with green building standards, redefining HVAC as a cornerstone of sustainable infrastructure.

Custom Motors in the Oil and Gas Sector: A Case Study

A leading North American oil and gas firm revolutionized its offshore drilling with custom motors, cutting operational costs by 25 percent. Engineers developed brushless DC motors for submersible pumps, delivering high torque at depths exceeding 10,000 feet. These motors featured permanent magnets for compact, lightweight designs that eased rig installations. Temperature controls withstood 200°F subsurface heat, while voltage specs handled 690V supplies. Bearings coated for corrosion resistance prevented failures in saline waters. The case study highlights how mechanical engineers iterated prototypes, reducing inductance for efficient power transmission. Custom motor parts, sourced from reliable distributors, ensured quick field repairs. In this motors custom application, single phase backups provided redundancy during main power outages. Related queries on custom motor build illustrate the project's scalability to onshore pipelines. Adhering to IEC standards, the motors boosted extraction rates without increasing energy use. This success story demonstrates custom motors' transformative power, enabling safer, more productive operations in one of the world's toughest industries.

Choosing the Right Distributor for Custom Motors

Factors to Consider When Selecting a Distributor

Selecting a distributor for custom motors demands scrutiny of expertise, inventory, and support to secure reliable supply chains. Prioritize partners with deep knowledge in AC and DC variants, ensuring they understand applications from HVAC to oil and gas. Look for those offering comprehensive information on custom motor parts, including bearings and windings tailored to torque needs. Lead times matter—choose distributors with robust manufacturing ties to avoid delays in custom performance motors. Certifications like NEMA and IEC compliance signal quality for North American markets. Evaluate their engineering support; top distributors provide consultations with mechanical engineers for optimal selections. Cost transparency, including weight-based shipping for bulky torque motors, prevents surprises. Searches for electric custom motors often point to distributors stocking brushless options for emerging needs. Reliability in wastewater or high-temperature environments requires proven track records. In America, local presence speeds delivery and service. This careful choice ensures access to innovative, durable custom motors that propel projects forward without interruptions.

The Role of Mechanical Engineers in Custom Motor Selection

Mechanical engineers play a pivotal role in custom motor selection, bridging design intent with practical implementation. They analyze system requirements, specifying voltage, torque, and temperature ratings to match operational demands. For HVAC integrations, engineers favor AC motors with low inductance for quiet efficiency. In oil and gas, they opt for DC variants enduring extreme conditions. Their expertise evaluates weight impacts on machinery balance and bearing choices for longevity. Collaborating with distributors, engineers access detailed specs on permanent magnet motors for high-performance needs. Searches for motor custom build emphasize their iterative testing to refine selections. In wastewater setups, they ensure motors handle corrosive loads without voltage drops. NEMA standards guide their choices for seamless installations. By forecasting lead times for custom parts, engineers prevent project bottlenecks. This hands-on involvement guarantees motors not only fit but exceed expectations, driving engineering excellence across industries.

Understanding Lead Times and Custom Motor Parts Availability

Lead times and parts availability dictate the feasibility of custom motor projects, influencing timelines from concept to deployment. Standard AC motors ship quickly, but bespoke designs for torque or brushless DC applications may take 8-12 weeks due to specialized fabrication. Distributors with in-house engineering shorten these by stocking common components like bearings and magnets. For oil and gas urgency, prioritize suppliers offering expedited custom motor parts assembly. Voltage-specific windings or temperature-resistant enclosures add complexity, extending waits. In America, regional hubs reduce shipping delays for heavy, weighty motors. Related searches for customized motors stress transparent communication on availability—top distributors provide real-time inventory via portals. Mechanical engineers factor these into planning, selecting partners with global IEC-compliant networks. For HVAC retrofits, quick access to single phase parts minimizes downtime. Understanding these dynamics ensures smooth procurement, turning potential hurdles into streamlined successes for innovative applications.

Future Trends in Custom Motor Technology

The Rise of Brushless DC Motors in Custom Applications

Brushless DC motors surge in custom applications, offering superior efficiency and reduced maintenance for demanding sectors. Eliminating brushes cuts wear, ideal for continuous HVAC operations or oil and gas pumps. Engineers customize BLDC motors with high torque density, integrating sensors for precise speed control via electronics. Low inductance enhances responsiveness in variable-load wastewater systems. In America, their adoption aligns with energy mandates, slashing power use in single phase setups. Distributors now prioritize these for custom motor vehicles, like electric drivetrains in industrial carts. Permanent magnet integration boosts performance without added weight. Searches for bldc motors reveal growing interest in IoT-enabled versions for predictive analytics. Mechanical engineers design them for extreme temperatures, ensuring reliability in remote sites. This trend redefines custom motors, delivering quieter, longer-lasting solutions that adapt to smart manufacturing and beyond.

Permanent Magnet Motors: Efficiency and Performance Innovations

Permanent magnet motors innovate efficiency and performance, compacting power into lightweight frames for versatile custom uses. Rare-earth magnets generate strong fields, enabling high torque at low speeds—perfect for HVAC blowers or oil and gas valves. Engineers optimize designs to minimize inductance losses, improving battery life in DC-powered tools. Temperature stability prevents demagnetization in hot environments like refineries. NEMA frames standardize integration, while IEC compliance suits global exports. In wastewater, their corrosion-resistant builds endure harsh chemistries. Related queries on permanent magnet motors highlight custom power boosts for electric applications, including prototype vehicles. Distributors supply parts for easy upgrades, reducing lead times. Mechanical engineers leverage simulations to fine-tune voltage handling. This evolution promises 20-30 percent efficiency gains, positioning permanent magnet motors as frontrunners in sustainable engineering across industries.

The Future of Custom Motors in Emerging Industries

Custom motors evolve rapidly for emerging industries like renewable energy and automation, adapting to new challenges with cutting-edge features. In solar tracking systems, torque motors adjust panels for optimal sun exposure, incorporating brushless DC tech for precision. Engineers explore AC-DC hybrids for electric custom motorcycles and vehicles, emphasizing low weight and high voltage efficiency. Wastewater innovations extend to smart grids, where custom motors optimize flow with AI-driven controls. Oil and gas pivots to carbon capture, demanding motors resilient to chemical shifts. Searches for motors customization forecast growth in permanent magnet variants for robotics. In America, policy incentives accelerate adoption of lead-free, IEC-standard designs. Distributors enhance availability of parts for rapid prototyping. Mechanical engineers pioneer inductance-reduced models for faster responses. This forward momentum ensures custom motors fuel breakthroughs in sustainability and mobility, shaping a dynamic industrial landscape.

See Also

- Navigating the Landscape of Custom Motor Parts for Enhanced Performance

- The Role of Mechanical Engineers in Designing Custom Motors for Every Need

- The Impact of Temperature on Custom AC Motors and Their Applications

- Custom Motors for Wastewater Management Solutions Boost Efficiency

- How Custom Motors Revolutionize Performance in Custom Vehicles